HONGTONG BEARING CO., LTD.

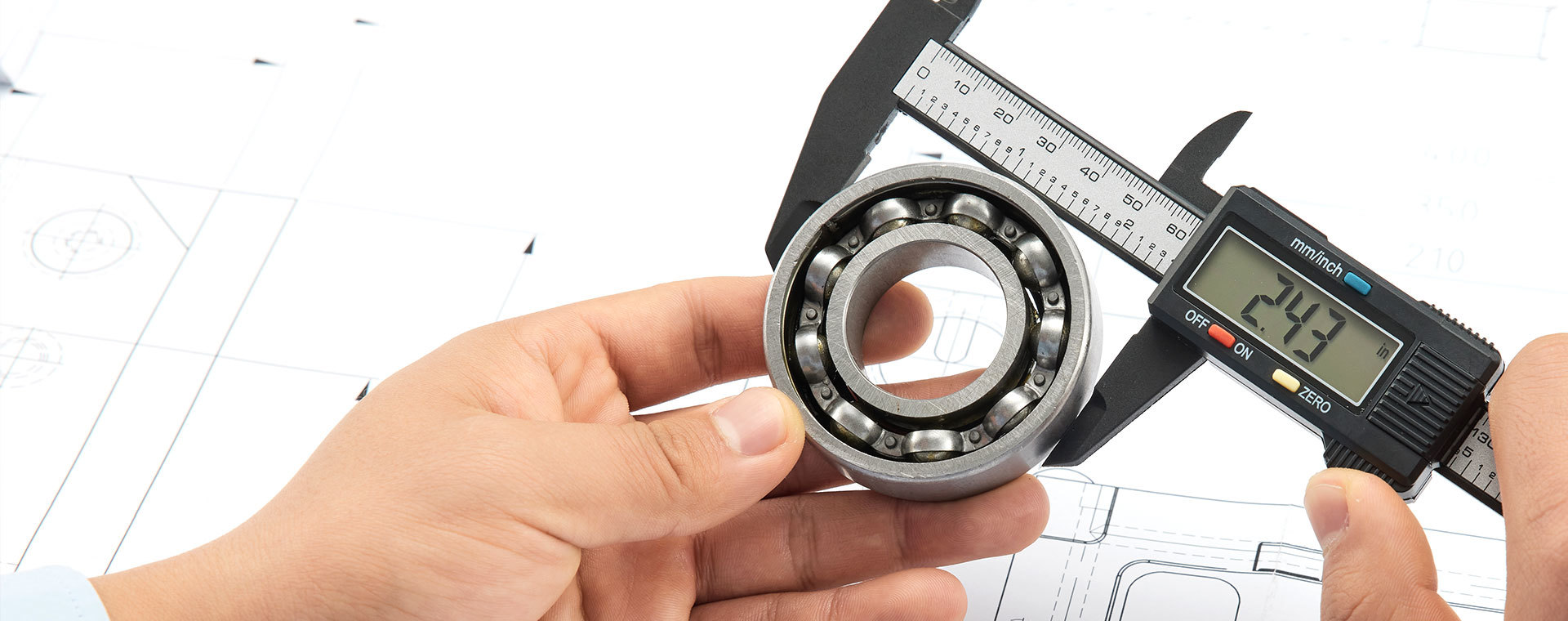

Shandong Hongtong Bearing Co., Ltd. was established in 2005 and is a professional manufacturer of various types of bearings. The company is located in Linqing City, Shandong Province, covering an area of over 10000 square meters. It has modern production equipment and advanced production processes. We adhere to the business philosophy of "quality first, customer first" and are committed to providing customers with high-quality bearing products.

Over 20 years of experience

Produced and sold more than 10 million sets of bearings

Marketing to 100 countries and regions around the world

30+ strategic partners

FOR RENOWNED MANUFACTURES

RELIABILITY. EXPERTISE. EFFICIENCY.

Hongtong Bearing are proud of the quality and consistency of the product and service provided to our customers. We have powerful technical support and customer service teams that keep an eye on your technical questions and sales process.

TECHNICAL SUPPORT

Unrivalled selection of high-quality bearings.

Customize special bearing.

DELIVERY SUPPORT

Within 48 hours delivery.

7x24x365 online services.

AFTER-SALES SUPPORT

Quality guarantee 12 months.

Easy return policy.

News

Special Working Condition Bearing Application and Protection Q&A

The core points are adapting to high-temperature performance and protection: in selection, prioritize heat-resistant material bearings (such as carburized heat-resistant steel, ceramic bearings) to avoid hardness reduction and accelerated wear of ordinary bearing steel at high temperatures; in lubrication, abandon conventional grease, select high-temperature synthetic lubricating oil (such as polyimide type) or solid lubricants (such as molybdenum disulfide coating) to prevent lubricant failure at high temperatures; in structure, choose open type or high-temperature resistant seals (such as metal labyrinth seals) to avoid high-temperature aging of rubber seals; in installation, reserve a larger thermal expansion clearance, use high-temperature resistant fasteners, and strengthen heat dissipation design to reduce the impact of the environment on bearing temperature.

Advanced Bearing Selection and Precision Grade Q&A

Bearing precision grades are mainly divided based on dimensional tolerance, rotation accuracy, and surface roughness. The common standard is the ISO standard, which is divided into five grades from low to high: P0 (ordinary grade), P6, P5, P4, and P2. Grade P0 has the lowest precision and low cost, suitable for general machinery with low requirements on rotation accuracy, such as agricultural machinery, ordinary motors, and conveying equipment; Grades P6/P5 are precision grades, suitable for scenarios with certain precision requirements, such as machine tool feed shafts, small and medium-sized motors, and automobile hubs; Grades P4/P2 are high-precision grades with minimal rotation error, suitable for high-end equipment such as machine tool spindles, high-speed centrifuges, and precision instruments, which can meet the precise positioning requirements under high-speed operation.

01-14

2026

Bearing Installation, Maintenance and Fault Diagnosis Q&A

Pre-installation preparations directly affect bearing service life, and the following points should be done: ① Cleaning: thoroughly clean the surfaces of matching components such as shafts, bearing housings, and end caps to remove oil stains, rust, burrs, and dust, avoiding foreign matter wear after installation; ② Precision inspection: confirm that the fit size, roundness, and cylindricity of shafts and bearing housings meet requirements without deformation or damage; ③ Prepare suitable tools: use special installation tools (such as sleeves, presses) to avoid directly striking bearings with hammers, preventing damage to rolling elements and raceways; ④ Apply an appropriate amount of suitable grease/oil inside the bearing or on the matching surface in advance according to the lubrication method.

01-07

2026

Basic Cognition and Daily Use Q&A of Bearings

The core function of a bearing is to reduce friction between rotating or moving parts of machinery, minimize wear, accurately position components, and ensure stable and efficient mechanical operation. It can be divided into two categories based on friction properties: rolling bearings and sliding bearings. Rolling bearings transmit friction through rolling elements (steel balls, rollers, etc.) and are widely used, such as deep groove ball bearings and tapered roller bearings; sliding bearings reduce friction by forming an oil film between contact surfaces with a lubricating medium, suitable for heavy-load, low-speed scenarios, such as engine crankshaft bearings.

11-30

2025

Choosing the Right One, Using It Well, Maintaining It Properly: A Practical Guide to Bearing Lubrication and Sealing

Statistics show that over half of early bearing failures are not due to fatigue damage, but rather to improper lubrication or seal failure. Proper lubrication and sealing are the most economical and effective ways to extend bearing life.

11-19

2025

The Cornerstone of Precision and Lifespan: In-Depth Understanding of Bearing Clearance and Tolerance Grades

When selecting bearings, "clearance" and "precision grade" are two crucial yet easily confused technical parameters. Together, they define the bearing's "character" and directly affect the equipment's operational performance.

YOUR PREFERRED SUPPLIER OF INDUSTRIAL SOLUTIONS